Posted on 2019-12-08 in

Process 3D Print, Support Removal, Laser Cutting, Polish

Material Plastic

Quantity 2 pcs

Price Range $1-100

Lead Time 2 workdays

Material Plastic

Quantity 2 pcs

Price Range $1-100

Lead Time 2 workdays

Gallery

About Project

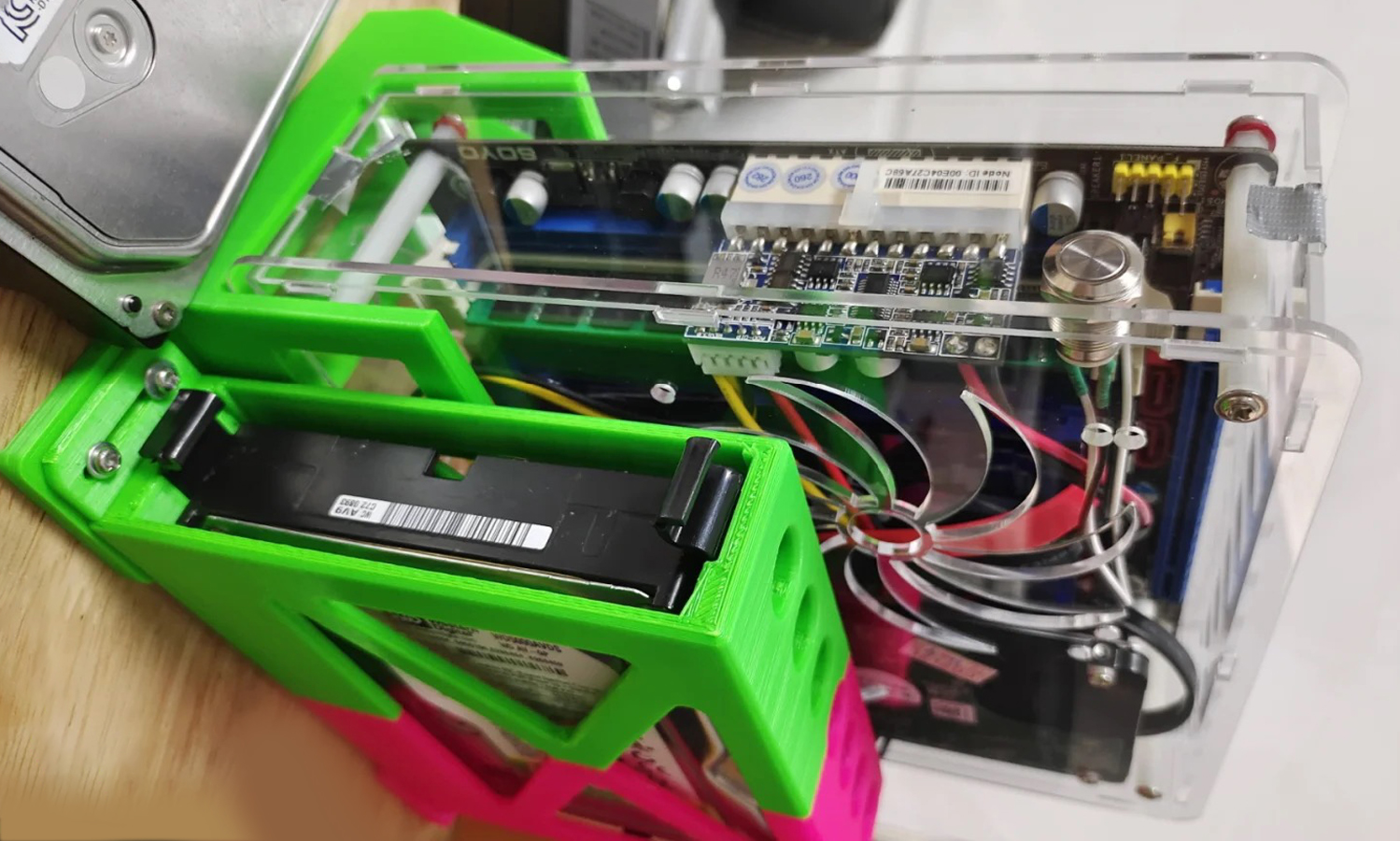

The client bought this secondhand NAS from a thrift store and designed the NAS enclosure by himself. He made a plastic case with his desktop FDM 3D printer, and came to us for PMMA manufacturing. Some of our clients really take pride in custom PC building.

Solution

- Step 1: The client measures the dimension of his medical devices, and builds the model of the enclosure, then exports the STL file for printing and the DXF file for laser cutting.

- Step 2: Here we print the parts with FDM 3D printing technology using FDM PLA, which is the most cost-effective solution for this application.

- Step 3: Take the prints from the plane. Adding a raft or skirt would make this process easier.

- Step 4: Polish the prints manually with grater and sandpaper to remove the remaining marks.

- Step 5: Laser cut the acrylic boards and drill holes as required. Finally, assemble all the parts with the devices, and fix them with screws.