Gallery

About Project

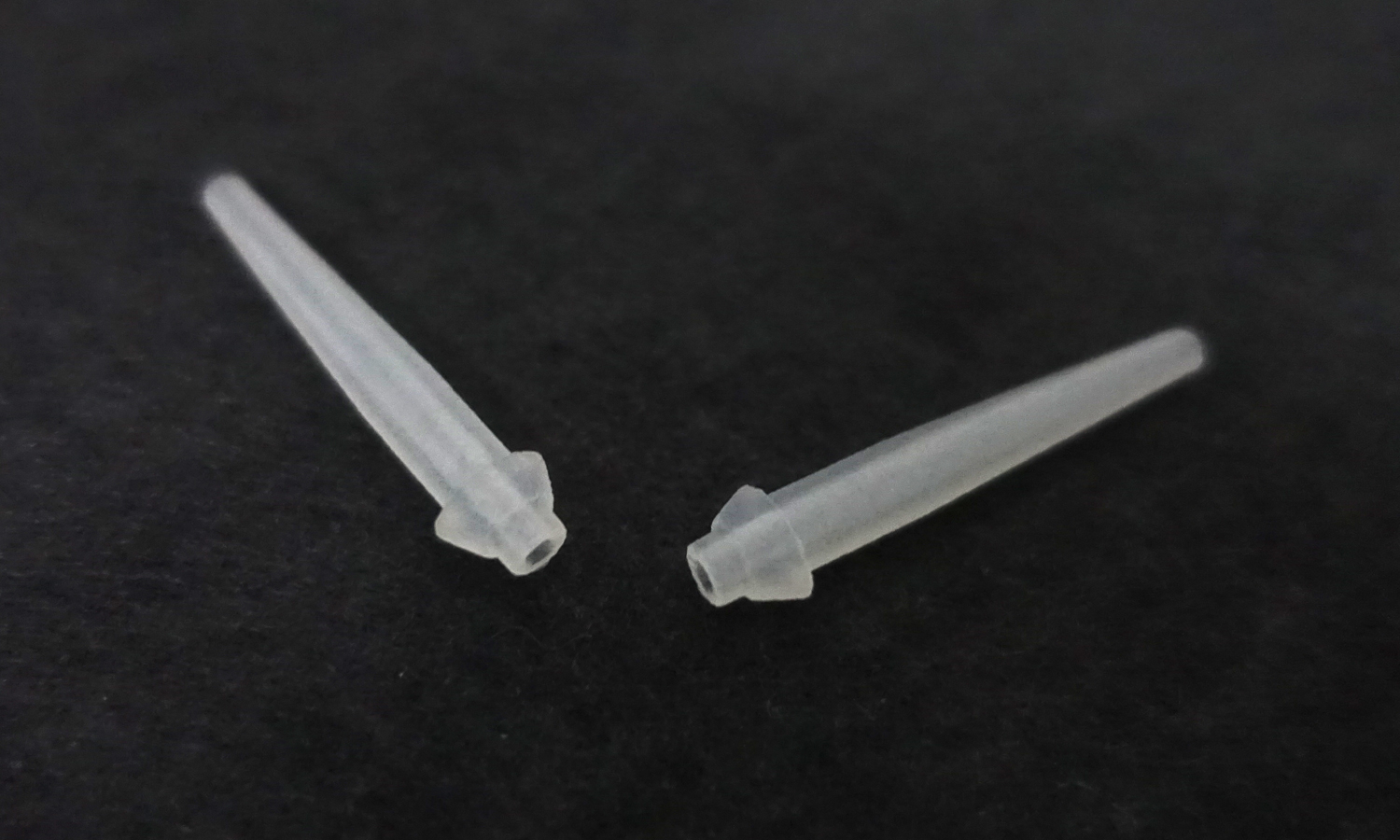

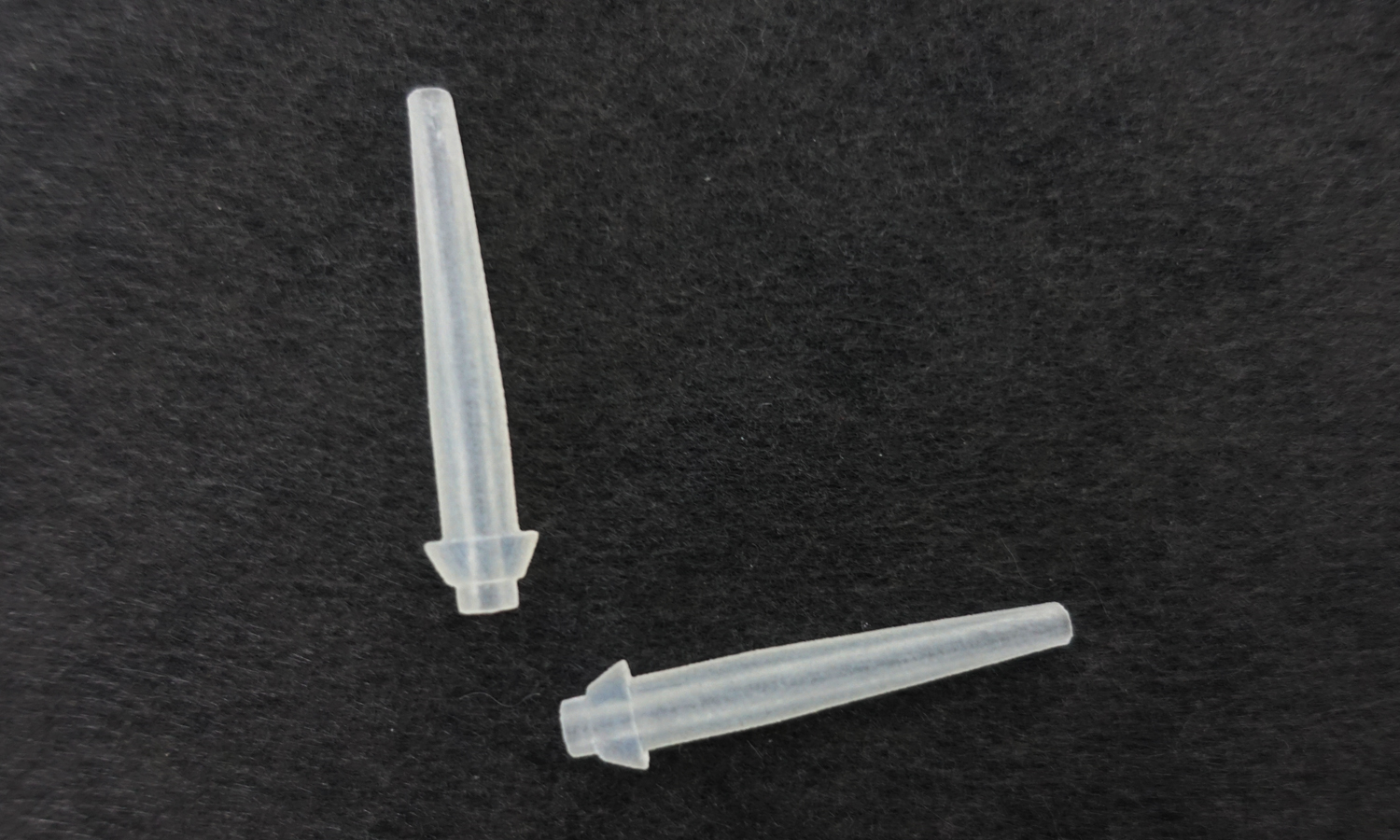

These tiny "soft nails" are made with PolyJet technology and rubber material. This soft elastic rubber has a durometer of 50A to give it a firm surface with a fair amount of pliability. It could be bent easily and return to the former shape quickly.

Solution

The PolyJet process begins by¬Ýspraying small droplets of liquid photopolymers in layers that are instantly UV cured. Voxels (three-dimensional pixels) are strategically placed during the build, which allow for the combination of both flexible and rigid photopolymers know as digital materials.

PolyJet uses a print head equipped with multiple jets to spray tiny droplets of liquid photopolymer 42 microns (0.00167¬Ýin.) across, forming layers just 30 microns (0.00118¬Ýin.) thick. These layers are then rapidly cured by an ultraviolet light source. Support material is printed at the same time, so PolyJet parts are self-supporting. When the build is complete, the part gets a quick bath in a chemical solution, dissolving the supports and leaving surfaces that are smooth and¬Ýaccurate.

One of the coolest things about PolyJet is its ability to mimic various polymers, including liquid silicone rubber (LSR) and ABS. What‚Äôs more, those materials can be printed in a range of hardness levels, making PolyJet a perfect choice for prototyping an overmolded electronics case, for example, or a housing cover with a built-in gasket, and doing so in a single build or run of the¬Ýmachine.