Posted on 2019-12-08 in

Process 3D Print, Support Removal, Post Curing, Primer Coating, Polish, Paint

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Material Resin

Quantity 1 pcs

Price Range $100-1,000

Lead Time 5 workdays

Gallery

About Project

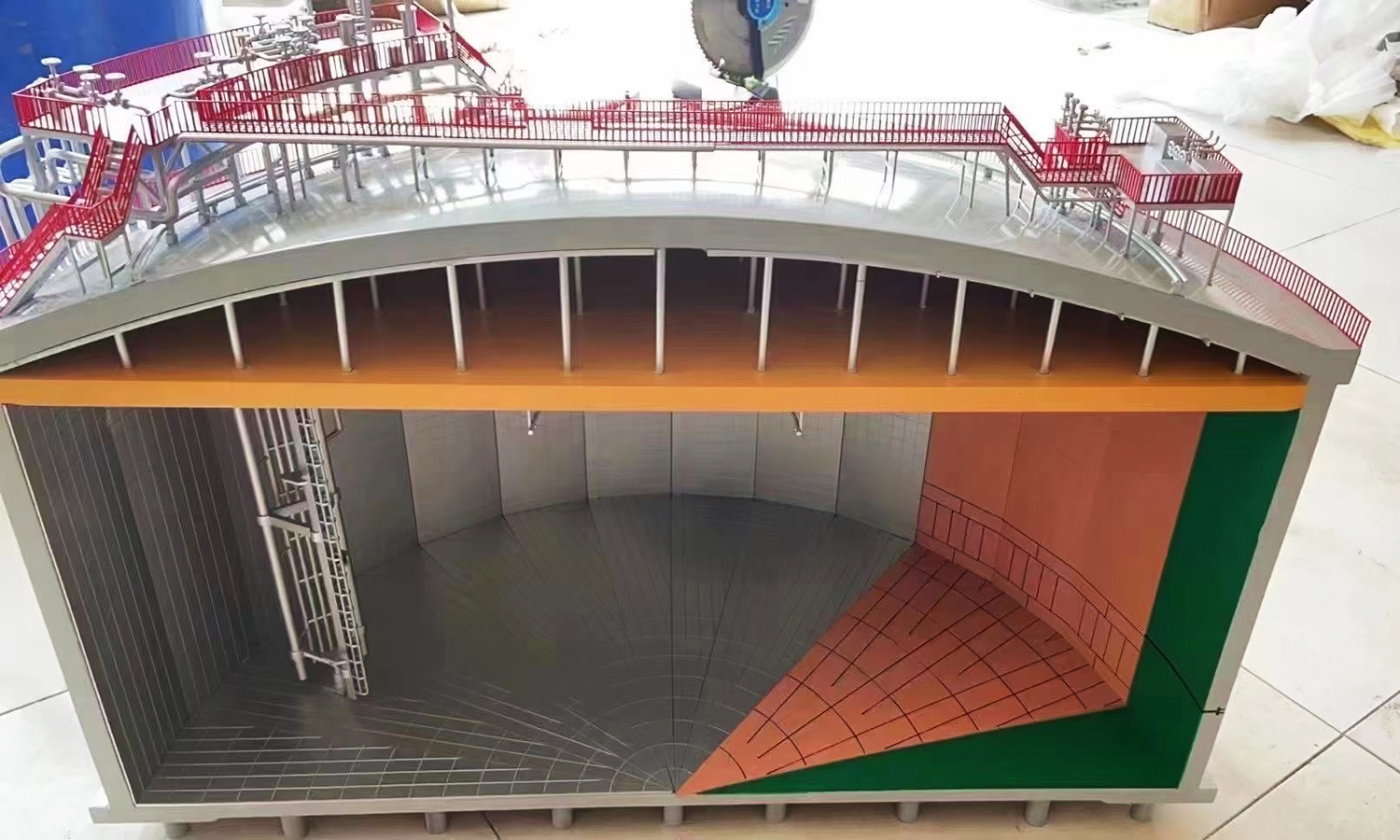

As the world leader in the construction of onshore long-distance oil and gas pipelines, CNPC is capable of designing and building 150,000m³ oil tanks and 10,000m³ spherical tanks, with an annual construction capacity of 26 million cubic meters for oil tanks and 16 million cubic meters for refined products. Here is a scaled-down display model for one of its largest oil storage tanks.

Solution

- Step 1: We firstly analyze the 3D models and found the challenges: the oil storage tank is quite large and easily deformed during printing, and the handrails are long and thin with overhang structures.

- Step 2: For these barrel-shaped objects, we usually print the bottom and wall separately. It's also useful to prevent deformation by adding supports and arranging the placement. We split the models into tank wall, bottom, top, handrails, small devices, and ladder.

- Step 3: 3D print all the parts with SLA Generic Resin using our industrial 3D printer. The layer thickness we set is 0.05mm.

- Step 4: Rinse the models with IPA and post-cure with UV. Cut off all the supports, then polish with sandpaper.

- Step 5: Paint the parts with red, silver, and grey paints. Screenprint the company logo onto the wall. Then spray with clear acrylic paint. Finally, glue all the parts together.