Posted on 2019-12-08 in

Gallery

About Project

ColorJet 3D printing technology can produce full-color parts at very low costs and is often used to 3D print figurines and topographical maps. Although the plaster powder is coated with glue to improve part strength, the prints are very brittle and are not recommended for functional applications.

Solution

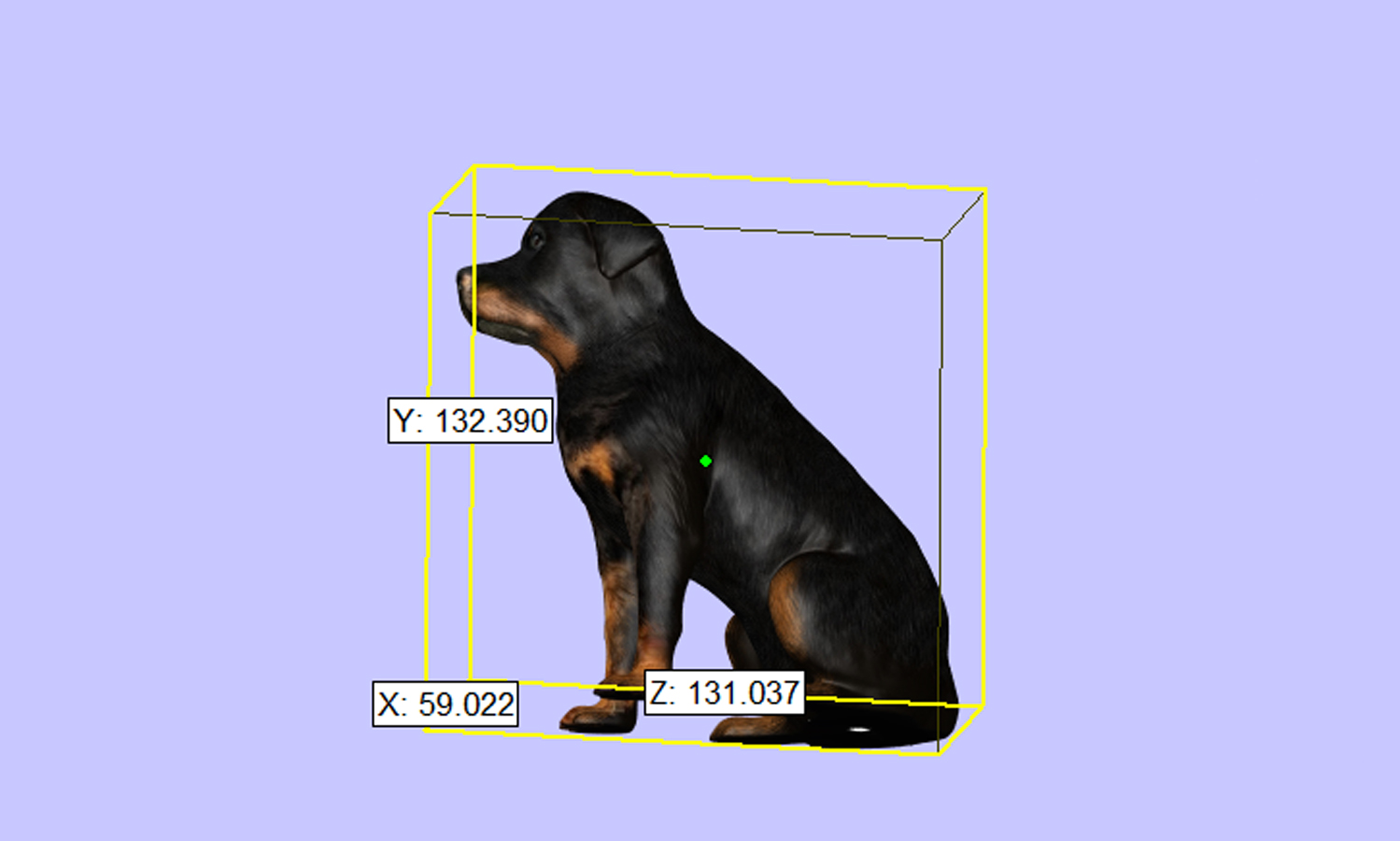

- Step 1: To produce full-color prints, a CAD model that contains the color information need to be built. Based on the photos sent from the client and other pictures on the Internet, our modelers build the 3D model of the Rottweiler dog.

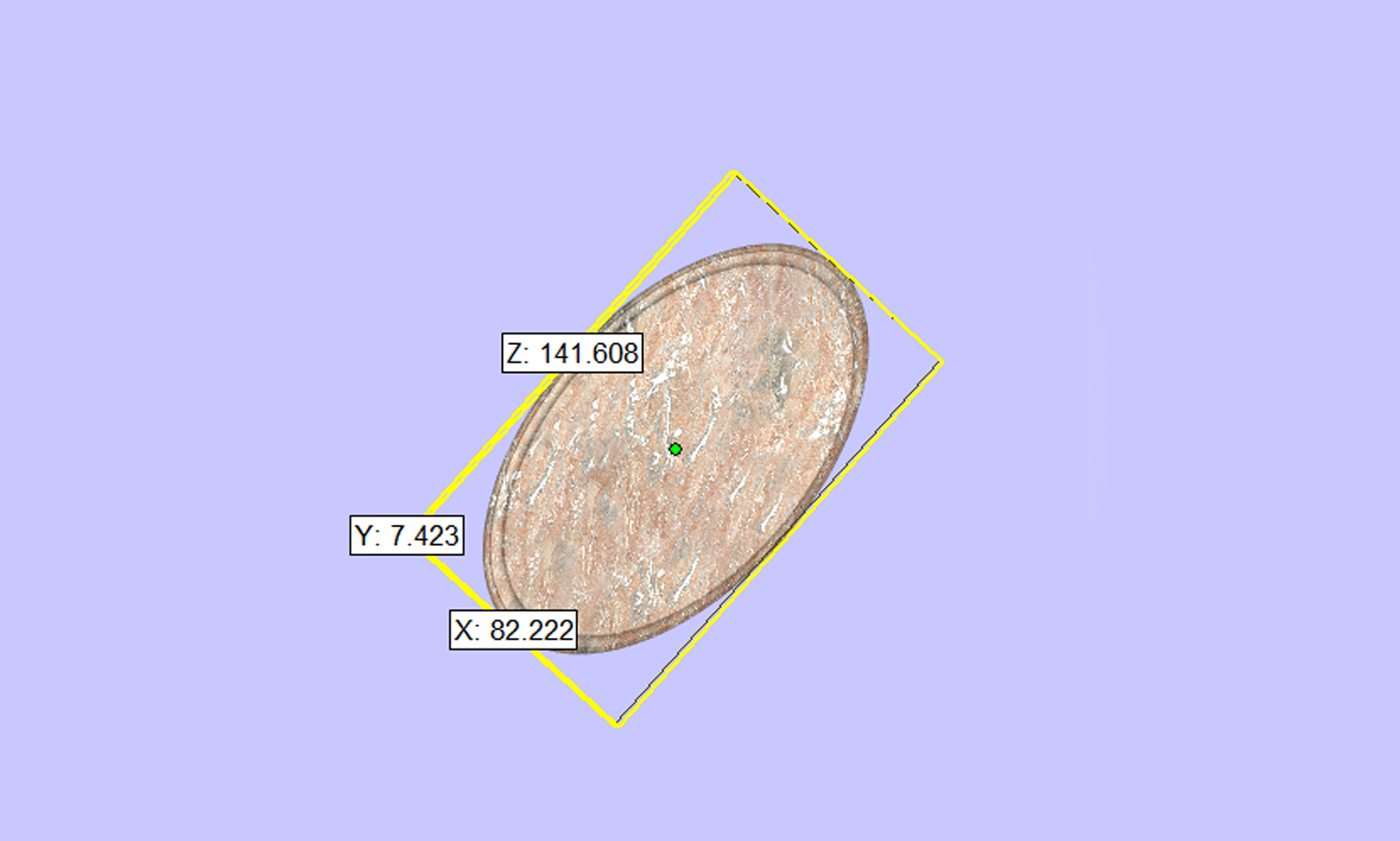

- Step 2: A rolling batch leaves a uniform layer of sandstone-like powder. From there two printing heads pass over the batch, coloring and adhering to the object at the same time. The batch of powder then makes another pass, until the object is completed.

- Step 3: After printing, the parts are then coated with cyanoacrylate (super glue) or a different infiltrant to improve part strength and enhance the vibrancy of the colors. A secondary epoxy layer can then also be added to further improve strength and color appearance.