Posted on 2019-12-08 in

Process 3D Print, Laser Cutting, Polish, Glueing

Material Other

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Material Other

Quantity 1 pcs

Price Range $1-100

Lead Time 5 workdays

Gallery

About Project

It's a gift set made with two different technology: 3D printing and laser engraving. Both of them start from a few photos.

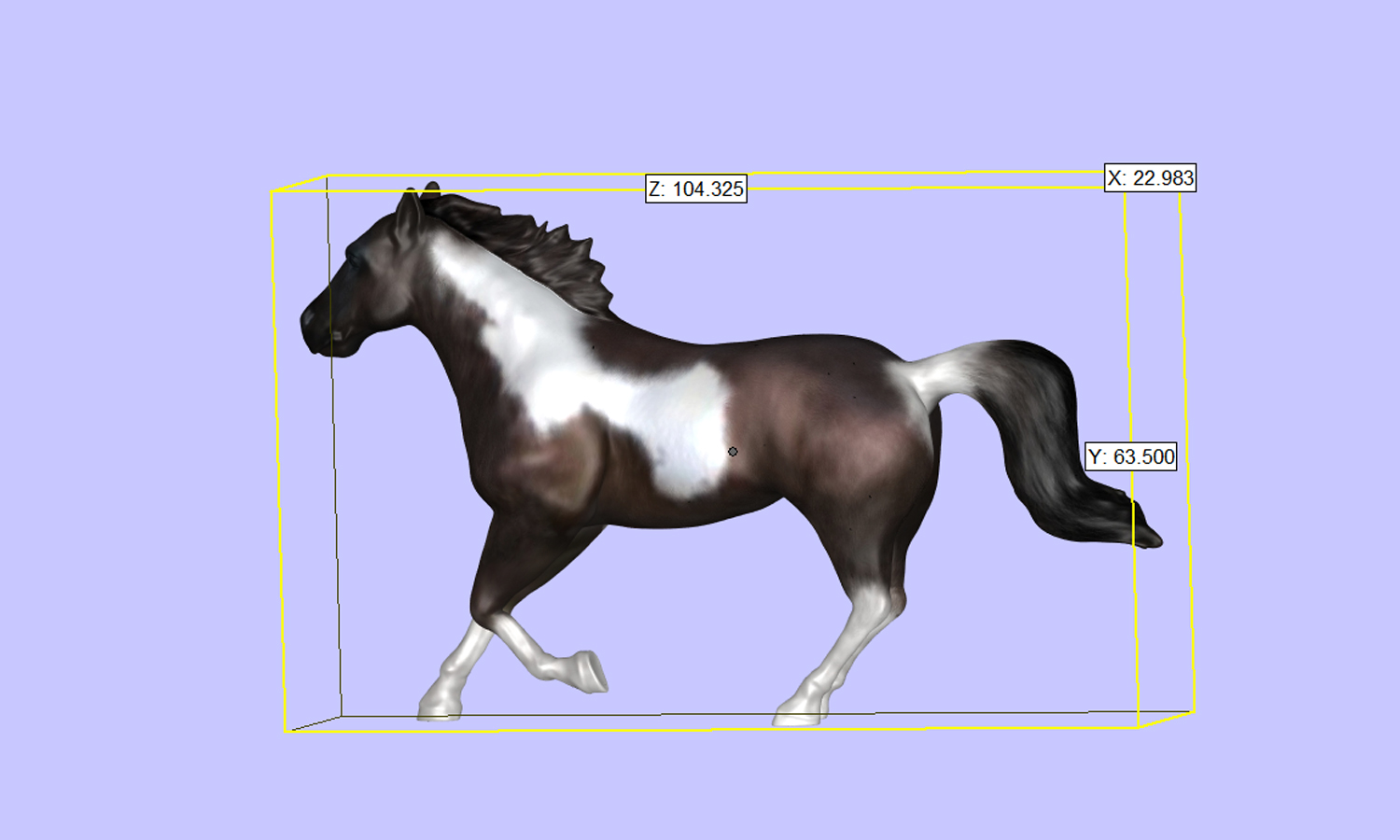

We built the 3D model from the photos of the horse and added a base to it. Then 3D printed the 63mm-high horse model with ColorJet printing technology, which cost less than $40.

As for the photo of the lady preserved in the 3D crystal brick, we also sell it on our Etsy shop and upgrade it to LED lighted brick.

Solution

- Step 1: As the material is painted during the process, the file uploaded to our website must also contain the texture information.

- Step 2: The process for 3D printing in sandstone begins with a bed full of plaster powder. A binding agent is added to the area of the powder that outlines the print, layer by layer, solidifying the powder into a sandstone-like material.

- Step 3: As the binding agent is applied, a color jet, similar to those seen in most laserjet printers, injects color specific to your model. Color is added to 3D models ahead of printing with special software.

- Step 4: Because sandstone prints are created in a powder bed, there is no need for any supporting structures on complex prints. The powder in which the print occurs acts as a supporting structure for the print.

- Step 5: Additionally, because of the powder bed style of print, sandstone is not ideal for “closed” or non-hollow prints. It can dramatically raise the cost of a print as excess material will become trapped inside of the print.

- Step 6: Select the photo and send it to the laser engraver, set appropriate parameters like Material settings, Process type, Resolution, Raster algorithm. Then begin engraving.