Posted on 2019-12-08 in

Gallery

About Project

The electrical insulation of common electric wires can be stripped by small hand-held wire strippers. However, the high voltage cables are thicker and need a far larger stripper.

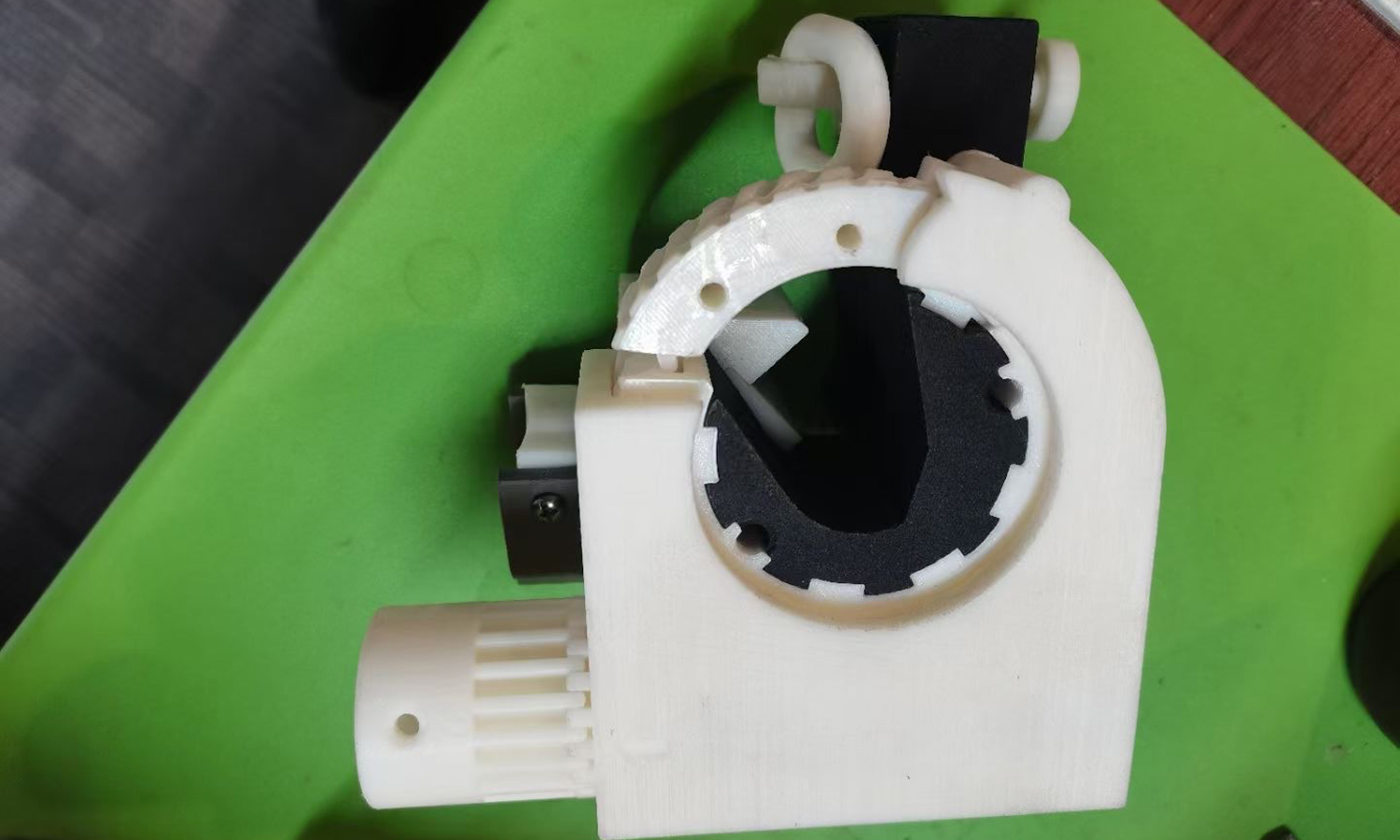

In this case, the client could not find the same one after breaking the old stripper. They were in a hurry as the construction would be postponed due to lacking spare parts. With 3D printing, we made a new enclosure of the large stripper at one time, and sent it with the fastest courier.

Solution

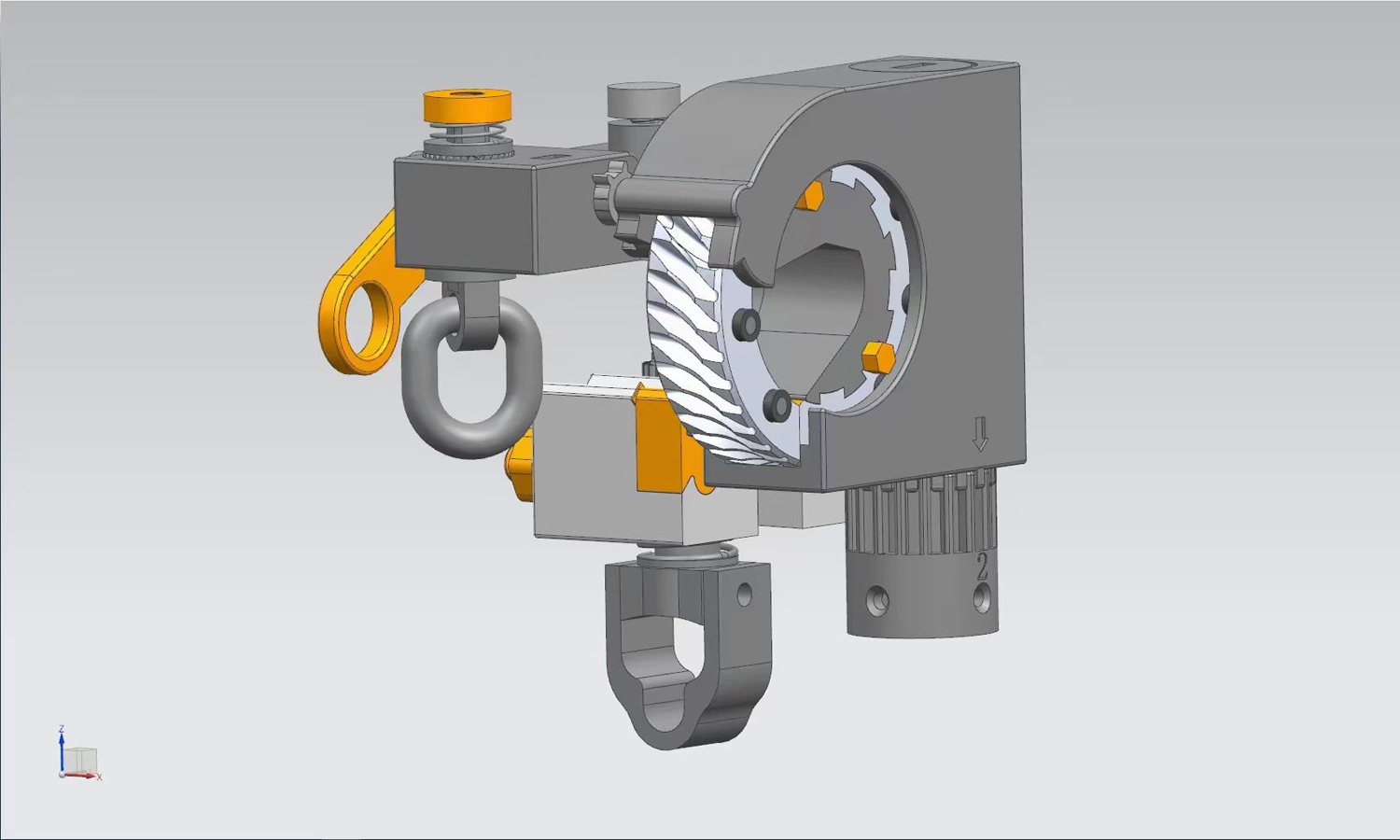

- Step 1: Our engineer studied the structure of the common wire stripper on market, and built the 3D model based on the 3D scans of the broken enclosure with reverse engineering technique.

- Step 2: 3D print the enclosure with Nylon 6 material and FDM printing technology. Nylon 6 offers the best combination of strength and toughness of any FDM material along with good impact strength, and it's insulative.

- Step 3: Simple post-process like cutting off the supports and sanding to remove the layer lines. Assemble the enclosure with the cutter and other parts.