Gallery

About Project

You definitely need some form of biological filtration in every aquarium – a filter is an easiest (and most common) option. They have multiple roles within an aquarium, but their main job is to clean the water. As water passes through, waste, debris, and toxins (like ammonia) are removed, leaving cleaner water to be released back into the tank. Your fish depend on this, otherwise it is easy for pollutants to quickly build up in the water. At low levels, most pollutants are not harmful, but they can become toxic at higher levels.

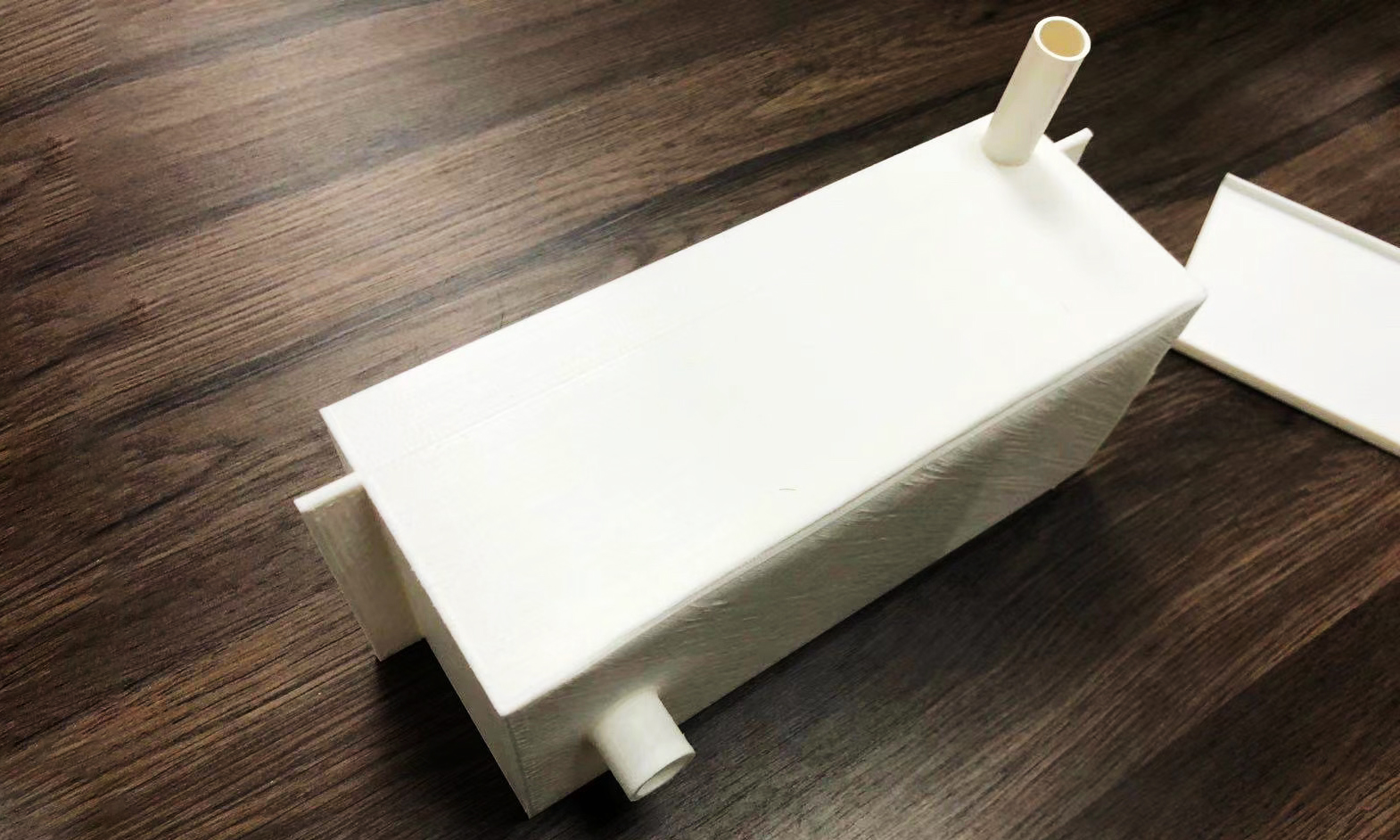

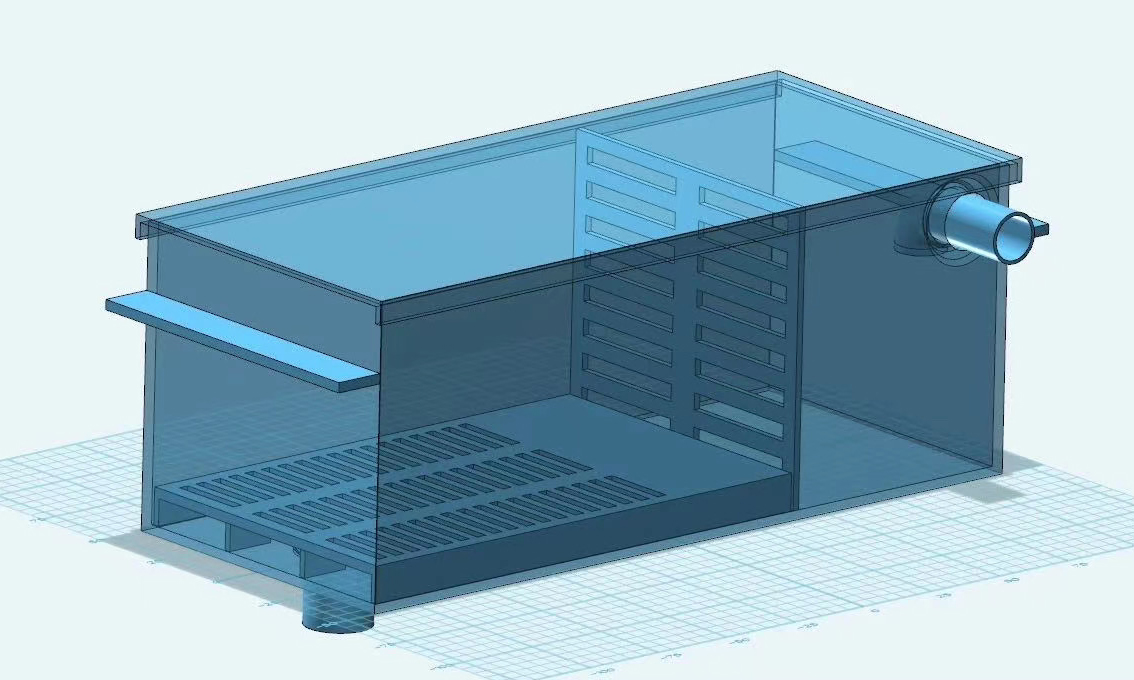

As the original enclosure of the filter has broken, our client redesigned a new and larger enclosure and ordered a print. The working principle is that the water pump pumps the water into the filter tank, and then water flows back to the fish tank from the outlet pipe at the bottom through various filter wool and other materials in the filter tank. A larger tank can hold larger filter wool, so the filtration efficiency can be improved.

Solution

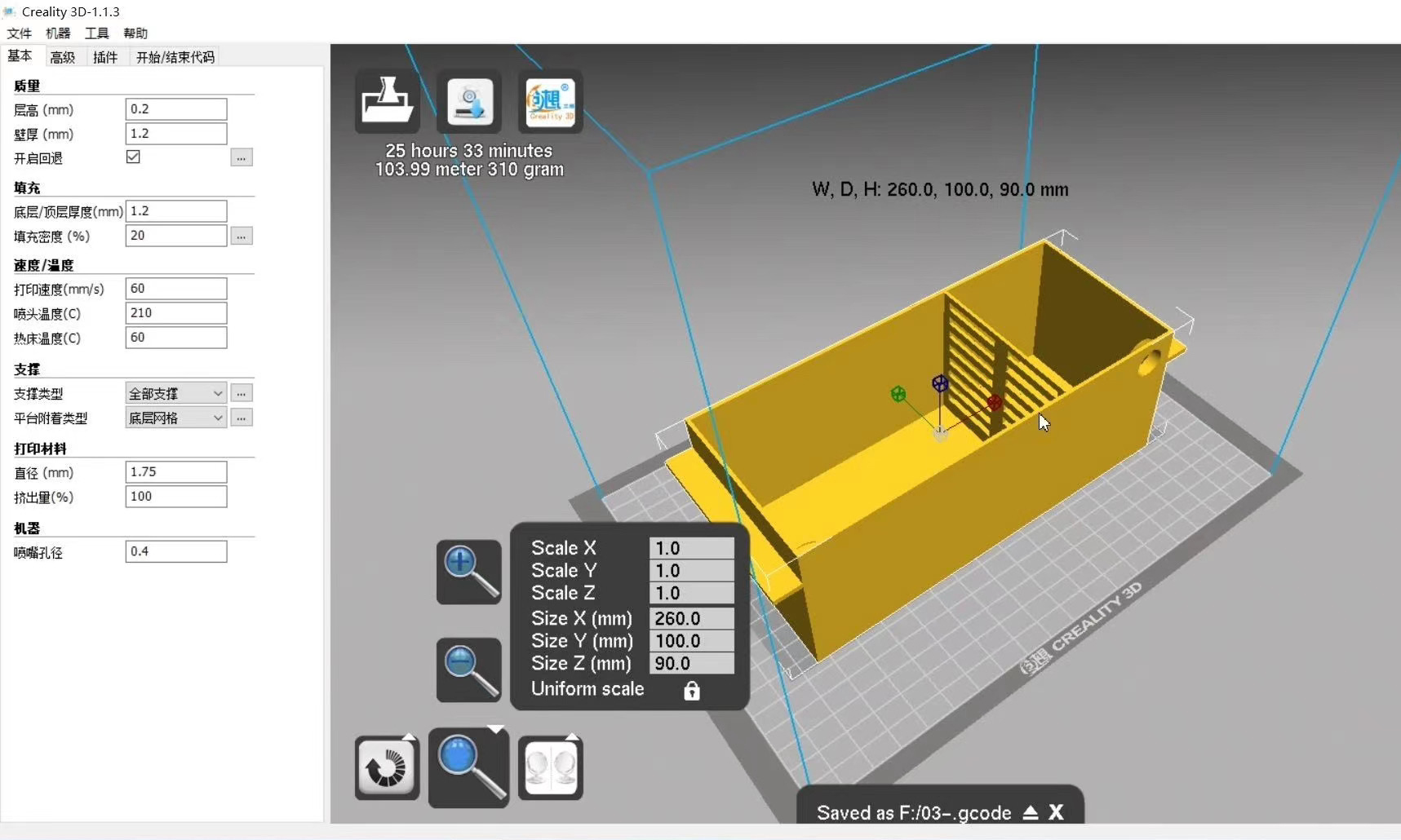

- Step 1: Help our client to adjust the dimensions of the filtration tank, such as the hollowed-out parts, the snap-fit structure, etc, to make it printable.

- Step 2: 3D print the assemble parts of the tanks with FDM 3D printing technology. We recommend using PLA, the monomer of which is typically made from fermented plant starch such as from corn, cassava, sugarcane, or sugar beet pulp, so it's safe enough for fish and shrimp.

- Step 3: Sandblast and polish the printed parts, then assemble them into the tank.